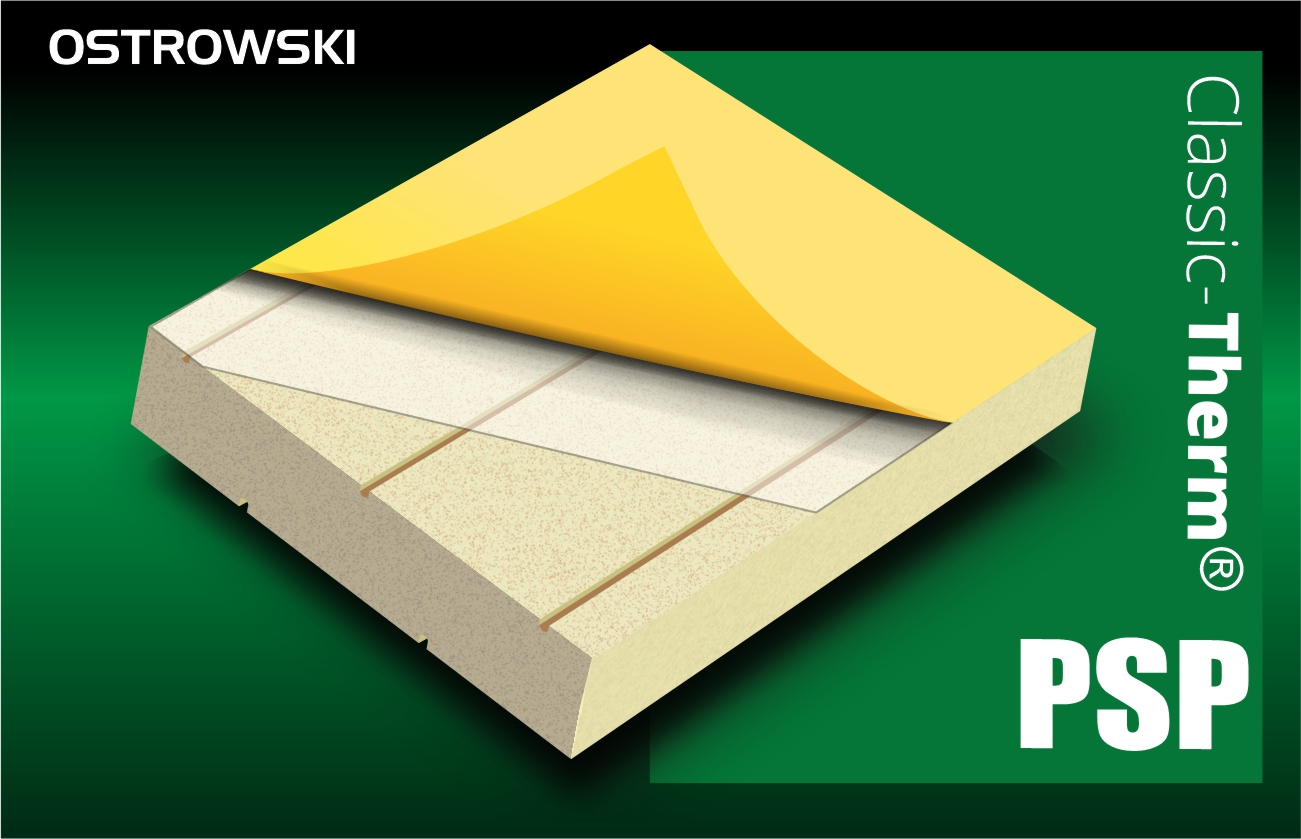

Self-adhesive foam sandwichelement

Self-adhesive foam sandwichelement. Classic-Therm® PSP self-adhesive foam is a self-adhesive panel made of XPS coated on both sides or on one side with a special glue, available in various thicknesses. The adhesive surfaces are protected with silicone paper. The inner layer is an XPS core (extruded polystyrene – CFC-free hard foam), which maintains long-lasting properties. XPS products produced in this way are characterized by a very low thermal conductivity and do not deteriorate, because the product is resistant to moisture and cyclic freezing and thawing. The PSP self-adhesive foam produced by us is intended, among others, as door fillings, composite panels for trailers and trucks, panels for printing, panels for doors, sandwich panels for winter gardens, window widenings or panels for building air handling units

Sandwichelement Self-adhesive Foam

The board with Classic-Therm® PSP glue is characterized by exceptionally high tensile strength. The closed-cell structure of the boards makes the products resistant to moisture and retains their functional parameters even when subjected to long-term, constant contact with moisture or water. XPS panels are resistant to compression despite their low weight, which allows them to be used in many demanding applications, where the panels are exposed to high pressure resulting from operational loads after installation. PSP self-adhesive foam does not rot and is resistant to biological corrosion.

Market of Self-adhesive foams

The market, such as the production of self-adhesive foams, includes various types of products, such as: acoustic foams for soundproofing from the outside, or various types of technical foams such as PUR, EVA, EPB, PVC, EPDM, CR produced for the needs of industry. As we know, the use of foams in industry is very wide. They are used for sealing, insulation, joinery, assembly and sealing of ventilation and air conditioning systems, for filling empty spaces, amortization and soundproofing, in the furniture industry, in the automotive industry, in construction, advertising, electronics. Currently, there are products on the market such as: Q-tape self-adhesive plates, SKS self-adhesive foam, Quick Tape, Cosmo Therm Quick Tape, Stadur SKS. As a manufacturer of self-adhesive foam, we recommend Classic-Therm® PSP boards, trying to ensure that each product leaving the production line is of consistent, high quality.

Adhesive foam boards in advertising

Printing panels belong to the group of multi-layer sandwich panels, and their core is polystyrene foam of any thickness indicated by the customer. When gluing the PSP self-adhesive foam with facings such as PVC, it is perfect for printing. The advantage of this type of panels is their lightness, with high stiffness, resistance to deformation and durability at the same time. The closed-cell structure of the foam (core) is responsible for this. At the same time, the foam boards can be easily processed and cut.

Classic-Therm® PSP self-adhesive foam and door fillings

Our wide offer includes products characterized not only by high-quality workmanship, but also by remarkable durability and functionality. Classic-Therm® PSP self-adhesive panels are used, among others, as the aforementioned door fillings. PSP foam is covered with an adhesive that supports the adhesion of the board surface with materials such as aluminum, steel, galvanized, PVC or HPL laminate. Classic-Therm® PT-fix foam is also worth mentioning. It is a 100% recycled thermoplastic plate. It is extremely light and at the same time very durable. The offer is completed by the “eco” version, i.e. the Classic-Therm® EPS-fix self-adhesive plate. It is a board with a polystyrene core covered on both sides or on one side with glue with a layer of silicone paper on the top layer.

If you have any questions about our product range, please contact us directly:

Sales representatives:

Kamil Nierychło ![]()

![]()

Sales Europe

email: k.nierychlo@ostrowski.eu

tel.: +48 508 312 910