Types of panels

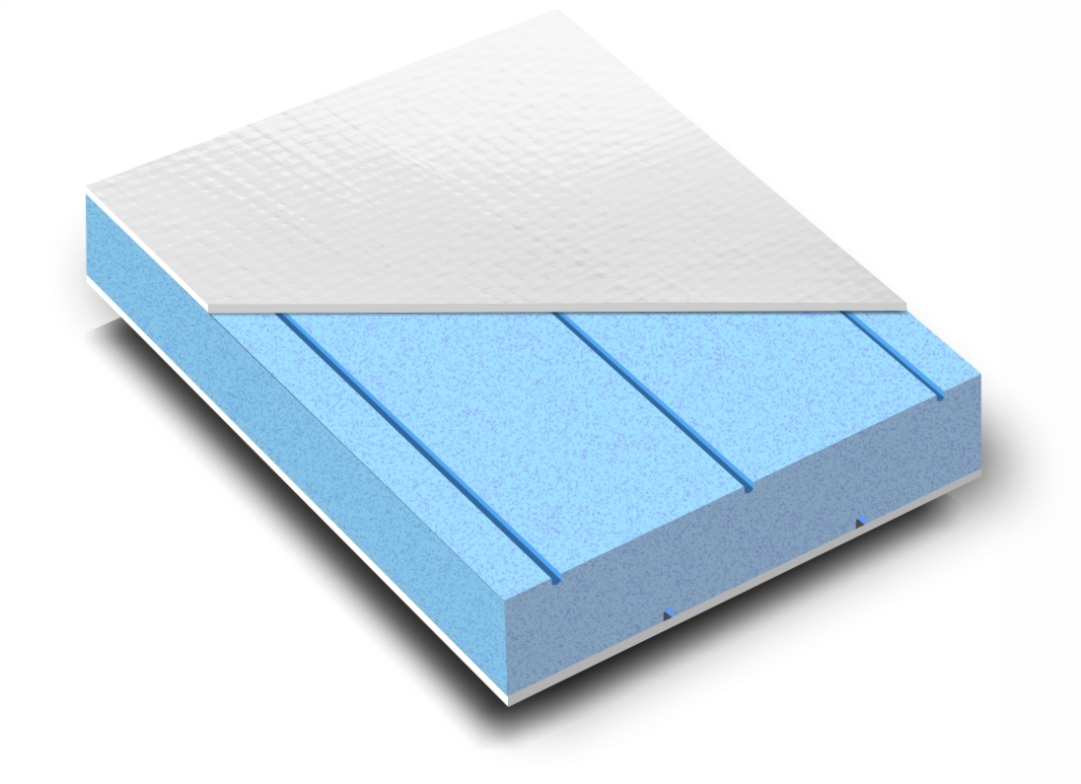

Classic-Therm® GFK powerlight

![]()

![]()

![]()

![]()

![]()

Sandwich panel with XPS core (extruded polystyrene), ideal as a trailers bodywork. A refrigerator trailers or a container trailers are types of delivery vans in which applied. The impact-resistant board is covered with a high-quality glass-polyester laminate with a special high-glass roving fabric.

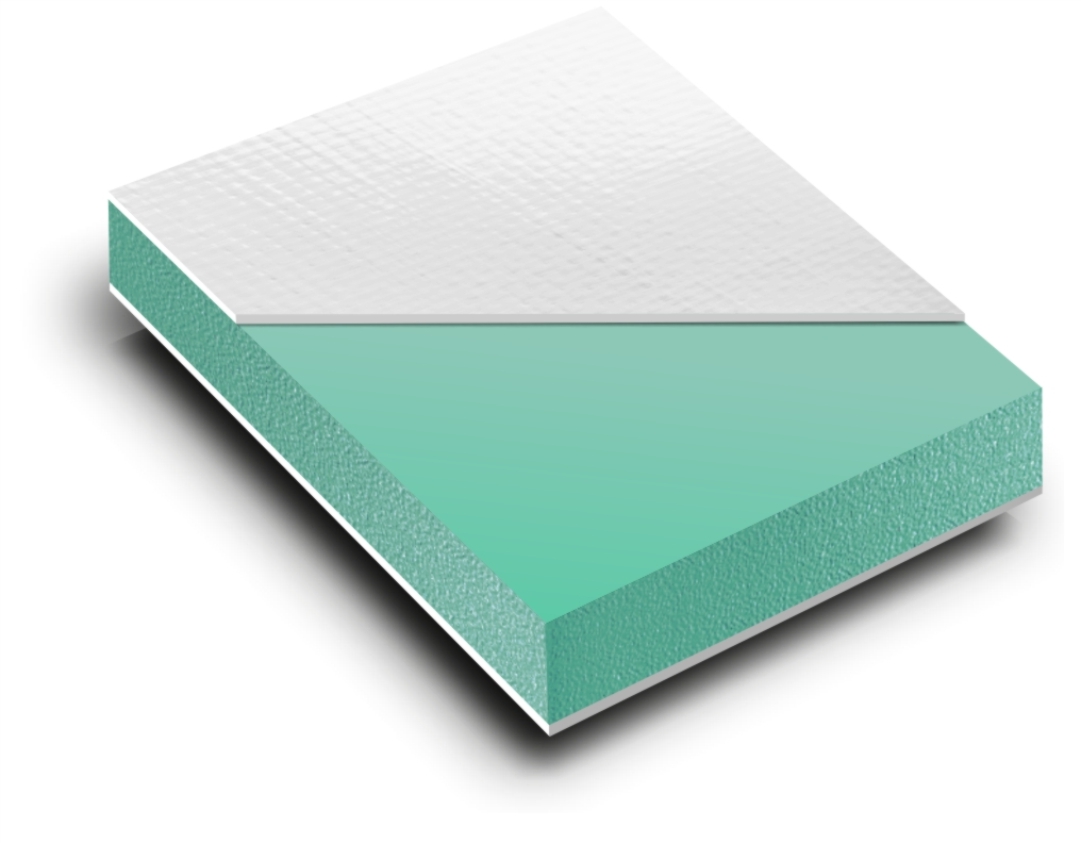

Classic-Therm® GFK powerlight HC

![]()

![]()

![]()

![]()

![]()

Sandwich panel for building trailers bodies on both sides of glass-polyester laminate with a very high glass content and a mesh with a special weave embedded in the material, which makes the material extremely resistant to impacts. The laminate has excellent resistance to UV radiation and weather conditions and is approved for contact with food. The core of the plate is a polypropylene honeycomb (HC).

Classic-Therm® GFK powerlight PUR

![]()

![]()

![]()

![]()

Composite panel for superstructures of car bodies, the core of which is PUR polyurethane foam. The outer layers consist of Powerlight laminate with a very high glass content and embedded roving fabric, which makes the material extremely resistant to impact and damage.

Classic-Therm® GFK powerlight PT

![]()

![]()

![]()

![]()

![]()

Composite panel for superstructures of car bodies. The core of the board is innovative PT foam 100% recycling with low weight and high mechanical strength. On the outside of the board there is Powerlight – a polyester-glass laminate with a very high glass content and a mesh embedded in the material. Surfaces resistant to UV and weather conditions.

Classic-Therm® GFK powerlight EPS

![]()

![]()

![]()

![]()

A sandwich plate designed for vehicle construction. The core of the board is EPS (expanded polystyrene), while the outer layer is made of impact-resistant Powerlight laminate with embedded special roving fabric.