Mission

The mission of the “Ostrowski” company is to build a leading position in the production of sandwich panels for joinery on the Polish market, and to develop a network of customers on European markets. We also try to use our experience in acquiring new market segments by offering innovative solutions using sandwich panels in which the core is extruded polystyrene (XPS). The assortment offer prepared by us, which includes not only high-quality PVC door panels, but also panels for automotive industry and advertising, is a response to the needs of a modern customer.

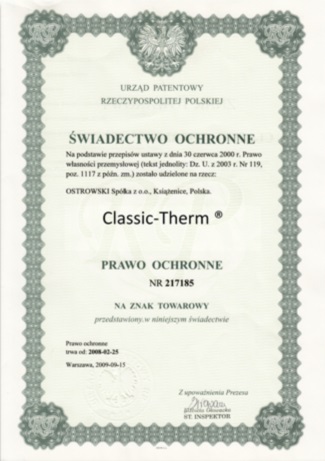

Certificates, awards and distinctions

History

In 1991 Mr. Krzysztof Ostrowski establishes a construction company dealing with, among others, construction works in the field of thermal insulation of housing estates, renovation of banks, schools and other facilities. In response to economic changes and interest of market, the company also conducted commercial activities in the RTV (1993-1997) and catering (1999-2004) industries.

In 2003, while looking for new areas of economic activity, a production line of sandwich panels for door panels was launched. The new business profile is run as a commercial law company called “Ostrowski” Sp. z o.o.

Due to the high quality standards imposed by the owner and an efficient trade policy, the company is gaining part of the domestic market within a few years and is also successful in exporting to Central and Eastern Europe. The company’s trading partners are mainly domestic and international wholesale networks.

Thanks to the energy market’s interest in ecological fuel, new business opportunities have emerged.

In 2008, “Ostrowski” acquires real estate near the intersection of A1 and A4 motorways and builds a reloading and warehouse base for mass products. The company has the appropriate equipment base, automotive fleet and warehouse halls. Regardless of reloading and storage of biomass, the company also conducts online retail sales of ecological fuel.

As part of the capital group, there has also been a company operating in the Internet trading in lighting, electrical equipment and accessories since 2006 (www.LuxMarket.pl).

The company’s development strategy in the coming years provides for further diversification of business activities within the capital group, in particular the expansion of the hardware base and infrastructure as well as undertaking projects in the field of “green” energy.

About sandwich panels

Sandwich panels – Europe – Poland

We have been producing sandwich panels of the highest quality for you for over 25 years. Poland and Europe are eligible for the delivery of our products.

Thanks to this, the solutions we propose are very popular among our clients. Classic-Therm® sandwich panels are a niche semi-finished product made by joining several flat elements. A characteristic feature common to all panels is their high stiffness and very low weight.

The sandwich panels we offer are used in many sectors.

Door fillings

Our offer includes a wide selection of sandwich panels such as: Classic-Therm® PVC, Classic-Therm® HPL or a special HCPP sandwich panel.

For the production of panels included in this category, we use high-quality PVC, HPL cladding, sheet – ALU, galvanized, wooden, as well as plywood and various types of laminates.

Additionally, some products use a special insert –– dB as acoustic insulation, or an ALU insert – with an anti-burglary function. As a result, our sandwich panels can be used in a variety of ways. Sandwich panels in the category: door fillings are used for the production of doors, gates, partition walls and windows.

Advertising sandwich panel

Our leading product is the lightweight Classic-Viscom® advertising panels. The light Classic-Viscom® foam board is easy to apply UV printing and applying various types of foil, thanks to which it is used in broadly understood advertising as signs, advertising boards, stands or spatial inscriptions.

In this case, we have the option of machining with standard tools. When using advertising panels with a foil print in outdoor conditions, it is recommended to use a UV protective laminate to increase the durability of the board. Our offer of panels includes many interesting solutions – such as PVCs plate, high-quality aluminum plate or Classic-Viscom HPL plate.

Vehicle construction

Sandwich panels in the Classic-Therm®GFK category are intended for construction of bodies of delivery vans, containers, cargo trailers or refrigerators. The thickness of the standard package offered is adjusted to the needs of our client. Heat transfer coefficient U = 1.35 (W / m2 x K). Plate thickness tolerance ( /- 1mm). Panels in this category are available in versions with different cores: XPS, PUR, honeycomb (HCPP) and PT foam. It is possible to order a standard laminate board, boards with the use of an innovative material such as non-slip GFK laminate, boards with Highgloss laminate with a high gloss or impact-resistant Stucco laminate with a structured surface.

Self-adhesive foam

A special product that is very popular is the Classic-Therm® PSP self-adhesive foam. It consists of a core (extruded polystyrene) and a double-sided self-adhesive foil. Thanks to its structure, the foam is widely used, among others as fillings for doors, windows, gates and partition walls.

Classic-Therm® PSP self-adhesive foam is available in the following formats: 2000 x 1000 mm and 3000 x 1000 mm. We offer foam with a thickness of 6 to 100 mm. The outer layer of the foam is resistant to weather conditions. It has an adhesive surface covered with silicone paper. PSP foam does not contain CFCs. The self-adhesive foam available in our offer is characterized by a compressive strength of 0.30 N / mm2 according to DIN 53421. Classic-Therm® PSP is a foam that is resistant to water – water absorption after 28 days is <0.7% according to PN- EN 12087 + A1.